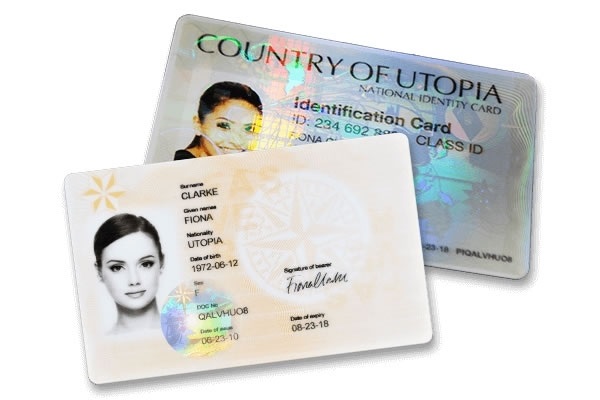

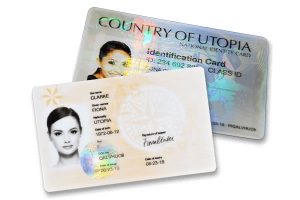

ID card design and production

ID card is a guaranteed solution for access control and authentication of people. There are different types of personal card; From the personnel card that is used to identify the personnel of the collections to the national card that is used to identify the citizens of the countries, they are all examples of various identification cards. Printing a good and functional personnel card is not a difficult task; A card printer used to print PVC cards is enough for people to print a simple PVC card or a high-quality personnel card. In fact, anyone with an ID card in hand can enter parts of a collection that they couldn’t without an ID card; This is where the high security ID card becomes important. But what features should a high-quality security ID card have?

Abilities and capabilities of the security ID card

– Production of all types of contact cards – contactless and combined with banking – identification (ID) – telecommunications – ticket cards and…;

– The possibility of using all kinds of materials PC-PVC (polycarbonate) – ABS and…

– Using the knowledge and experience of specialists in the entire production process;

– Benefiting from advanced machines to produce products with the control of criminal parameters;

– Having modern technology, in order to improve the security factor of products;

– Security and non-security design;

– Keeping manufactured products with the maximum level of supervision and security;

– Optimal presentation of products in minimum time.

Indicators and capabilities of implementing security and non-security parameters

– Laser engraving: Photo, writing, fingerprint, signature

– Inserting a chip (chip) – microprocessor or memory

– LOCO-HHCO-Mgstrip magnetic tape insertion (3 track)

– insert antenna (RF)

– Thermal printing – printing color and monochrome images

– Embossing letters and numbers

– Hologram and Kinigram insertion

– Insert tape and signature

Anti-counterfeiting ID card production standards

– ID.I format according to ISO 7810 standard

– thickness; 0.76mm

– corner radius; 3.18mm

– Dimensions 85.6mm*54mm

– Benefiting from modern equipment and technology in accordance with the ISO 1.373 standard in all stages of production and customization.

– Use of international standards; ISO: 7811 7813 7816 1444310536

• Printing with dry offset technology for all types of plastics such as ABS, PC, PVC, etc.;

• Cleaver for stacking papers;

• Lamination to fuse plastic sheets on top of each other;

• Card punch to separate plastic cards, according to the standard

ID-1 on plastic sheets;

• creating a hole for implanting a chip on the card;

• gluing the back of the chip;

• chipping on the card;

• Hot Stamping to install holograms, signature strips and scratch strips;

• Personalization with magnetic tape coding stations, chip coding, dye sublimation printing, laser engraving, etc.;

• RF circuit coding and embossing;

• Testing the durability of the chip on the card;

• Card bending test;

• card twist test;

• Card counting machine;

• Other laboratory equipment to control the quality and durability of the card.

Due to the security of the work and the confidentiality of some features, additional explanations will be provided in the face-to-face meeting.